Wire-Laser 3D Printing Expands Across Heavy Industries

Meltio’s wire-laser Directed Energy Deposition (DED) technology is steadily proving its industrial worth across demanding sectors like automotive, defense, aerospace, mining, and oil & gas. During the first half of 2025, companies have successfully used Meltio systems to produce challenging metal parts—such as a 300 mm high-temperature diffuser and a redesigned naval eductor for the USS Arleigh Burke—in record time and with improved material properties. These examples underline how its additive manufacturing approach allows for rapid, on-demand part production, reducing both costs and downtime.

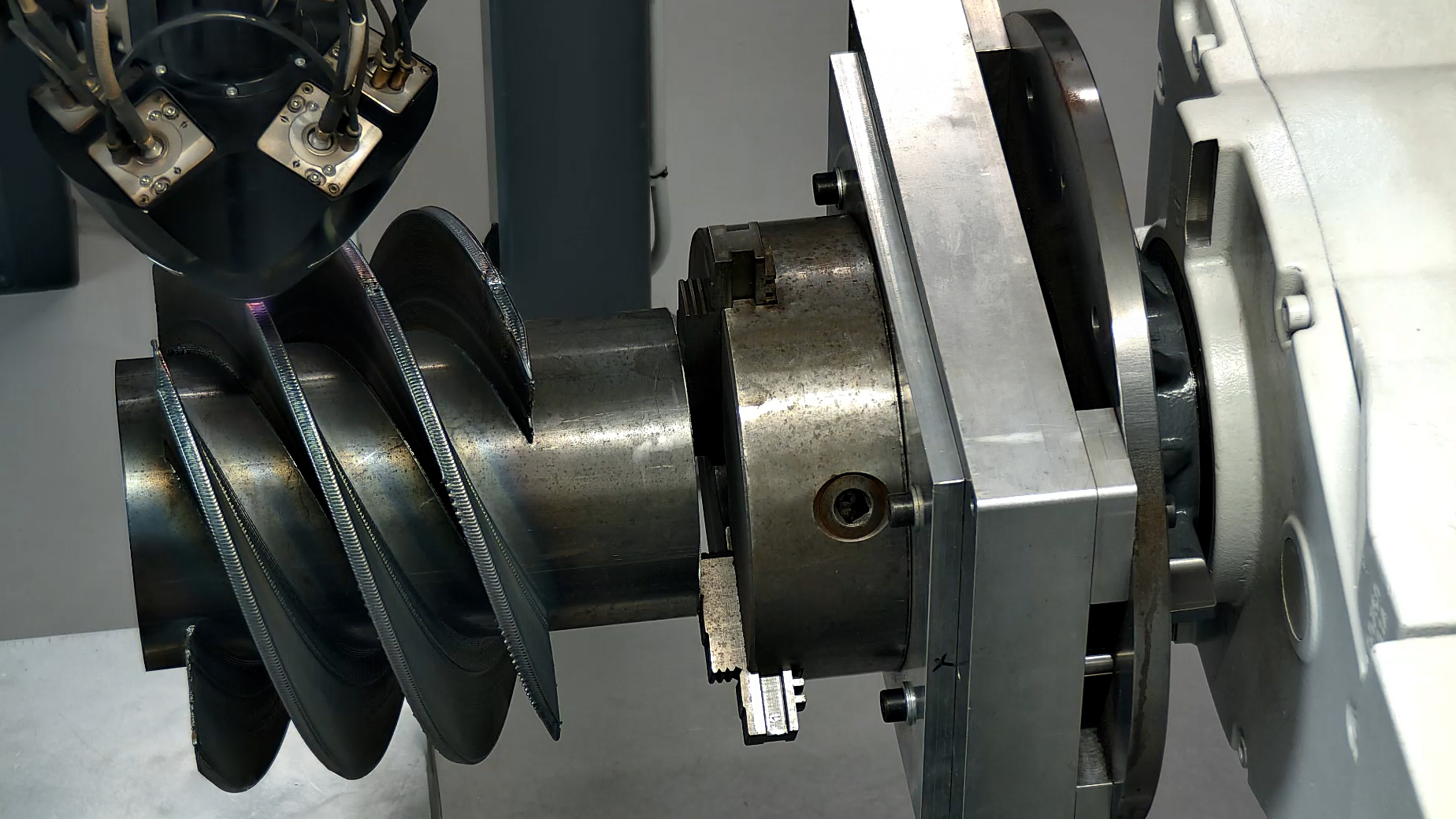

Beyond prototypes, Meltio’s systems have enabled printing of complex components in materials like stainless steel 316L to overcome corrosion and wear issues, which standout in environments requiring high durability. Additional use cases, like single-print turbine cases by Roez s.r.o., showcase the technology’s flexibility and efficiency—especially useful where traditional powder-based systems fall short. Notably, Meltio has earned the 2024 Enterprise 3D Printer of the Year (Metals) award for its M600 model—a recognition of the M600’s robustness and balanced design for machine-shop environments.

Across the globe, military organizations are adopting Meltio’s laser wire printing for on-site manufacturing and repair. The U.S., French, Spanish, and now South Korea’s armed forces have validated the technology, giving them autonomy over critical spare parts and reducing dependency on slow supply chains. For example, the Korean Marine Corps can now print discontinued or difficult-to-source parts in field conditions—a tangible edge in operational readiness.

Meltio’s rise signals a broader shift in how welding and fabrication integrate additive methods into everyday workflows. Its wire-based DED systems, designed for seamless integration with robots or machining centers, offer precision, multi-material flexibility, and reliability—attributes increasingly valuable in industrial welding and repair environments.

Source:

Discussion