Teaching Robots to Weld Could Ease UK Skills Crisis

The UK is facing a welder shortage that’s more than just a labor issue—it’s a looming industrial bottleneck. With nearly half the nation’s welders expected to retire by 2027 and fewer new entrants coming through vocational training, pressure is mounting on sectors like construction, aerospace, and shipbuilding. A new study from the University of Nottingham offers a potentially scalable solution: teaching robots to weld using the experience of human experts.

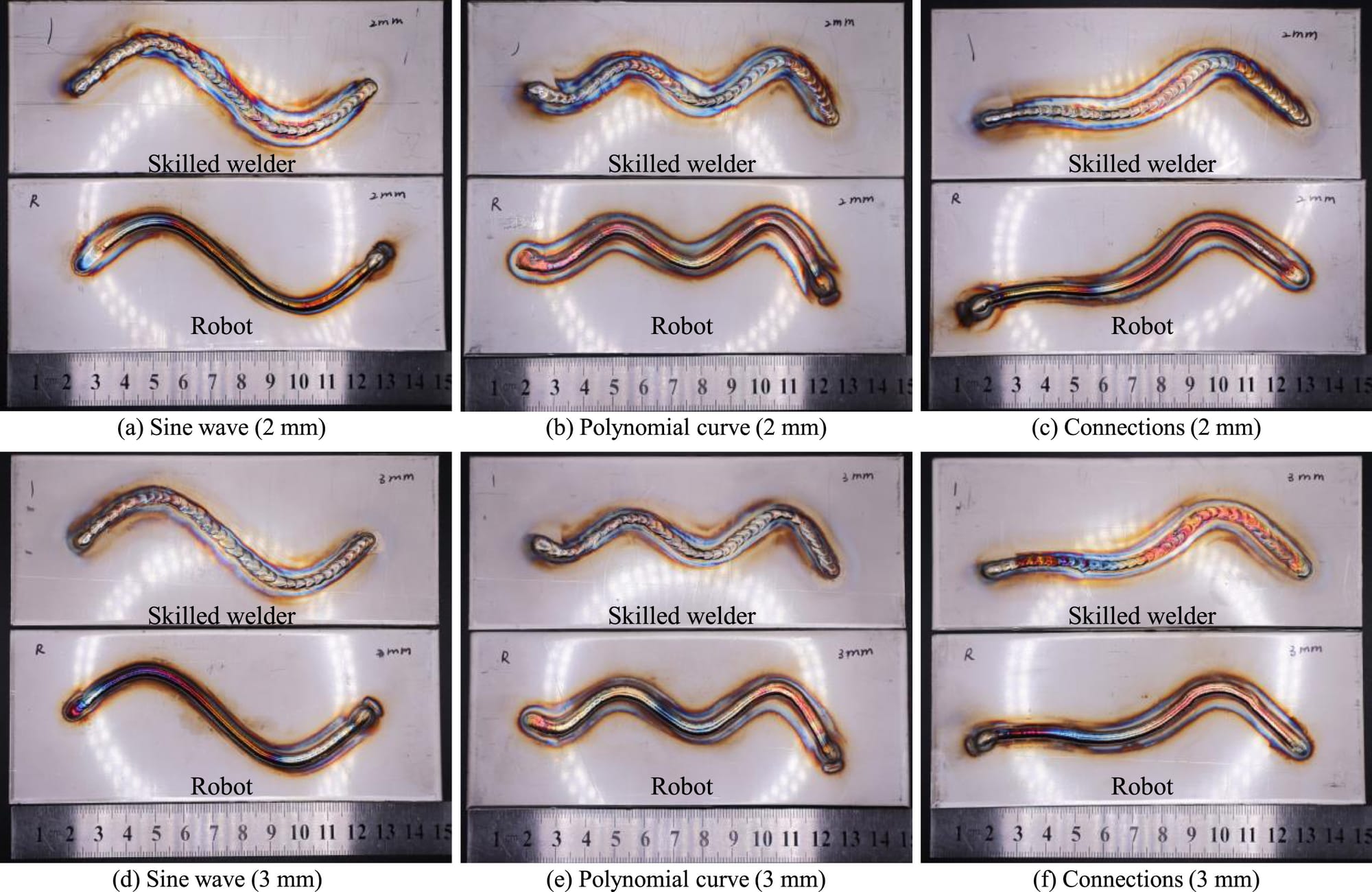

Researchers developed a robotic welding system that learns basic welding skills—torch angles, arc lengths, current levels—directly from seasoned welders. These actions are recorded, analyzed, and stored in a “skill library.” From there, the robot can plan and execute new, more complex welds, such as curved geometries, by combining learned tasks. The result? Welds comparable in quality to those made by skilled hands, but with reduced strain on the workforce and improved consistency in repetitive or hazardous tasks.

It’s not about replacing welders—it’s about rethinking their roles. As Associate Professor Abdelkhalick Mohammad points out, the goal is to relieve experts from routine jobs, allowing them to focus on problem-solving and innovation. The system could also extend to other manual trades like polishing or assembly.

The full study link is here.

Discussion