Machine Learning Tunes Laser Welding and 3D Printing

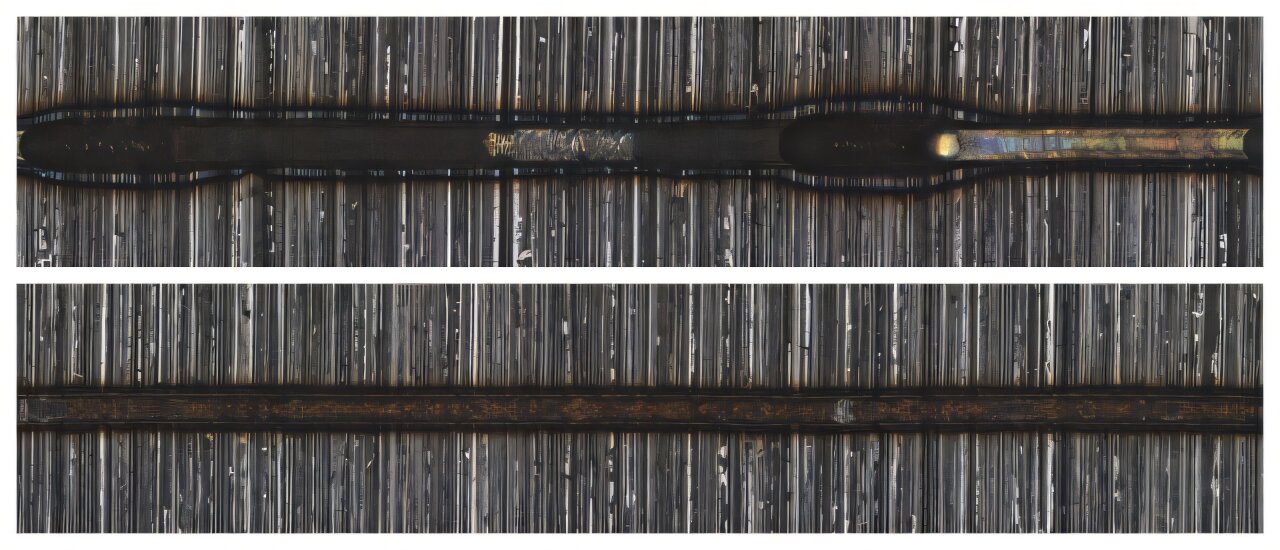

Laser-based manufacturing excels at precision, but it can be unforgiving when parameters drift. Researchers at Empa’s Advanced Materials Processing lab have trained a machine-learning model to read optical sensor data during powder-bed-fusion (PBF) trials, spot whether the process is in conduction or keyhole mode, and recommend the next scan speed and power settings. Early results cut the number of preliminary weld tests by roughly two-thirds without sacrificing quality—a practical gain for shops that find PBF too costly to dial-in on every new metal powder batch.

The same team has pushed the idea further for welding. By linking a field-programmable gate array (FPGA) to real-time sensors, the system can tweak laser parameters on the fly when it encounters surface defects—something human operators or conventional PCs struggle to do quickly enough. A standard computer still shadows the FPGA, updating the control model offline before it is flashed back onto the chip, keeping the weld loop deterministic and predictable.

Lower validation time in PBF and on-the-fly corrections in laser welding mean reduced scrap, faster changeovers, and a gentler learning curve for new talent entering the welding industry. Empa’s group is now working with machine builders to embed the firmware, a step that could make high-precision laser processes more accessible beyond aerospace and medical to smaller job shops looking for reliable, automated metalwork.

Source:

Discussion