Heat Treatment and Strength of WAAM Steels

Wire Arc Additive Manufacturing (WAAM) is becoming a serious alternative to traditional methods like casting and forging. Using gas metal arc welding (GMAW), steel parts can now be built layer by layer from wire feedstock. A recent study at Conestoga College in Ontario looked closely at how heat treatments after printing affect the mechanical properties of WAAM steels.

The results show that tensile strength, hardness, and toughness can be tailored by choosing the right post-printing process. For example, water quenching pushed ultimate tensile strength beyond 800 MPa, though with some loss in ductility. On the other hand, stress relieving at 600°C slightly improved notch toughness, even at the challenging test temperature of -60°C. The study also found that furnace annealing gave the softest results, while oil quenching produced values close to the as-printed steels.

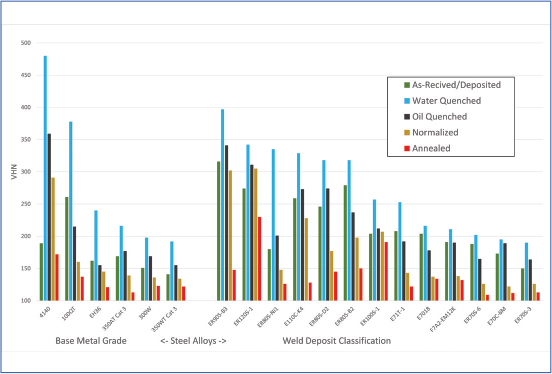

Hardness testing confirmed that WAAM steels respond much like conventionally processed steels: faster cooling gives higher hardness, while tempering controls excessive values. Importantly, the study noted little risk of embrittlement in mild steel WAAM alloys, even after rapid water quenching. This makes WAAM an attractive option for applications needing both strength and safety.

The work also highlights gaps in prediction models for hardness based on carbon equivalency, showing they don’t fully match WAAM results. Researchers recommend further development of models and testing of more alloys. With the right heat treatment, WAAM steels can reach strengths up to 900 MPa and maintain good ductility, opening opportunities for industry to design and print tailored steel components.

Discussion