Fronius CMT Turns 20: Cold Metal Transfer Milestone

Cold Metal Transfer (CMT) has spent 20 years redefining droplet detachment in welding. By reversing the filler wire at high frequency, the process slashes heat input by nearly a third and doubles welding speed versus conventional dip transfer. That cooler arc opened doors once closed to fusion welding—most notably the first thermal joining of galvanized steel to aluminum, a breakthrough that replaced solder or adhesive in many light-gauge assemblies.

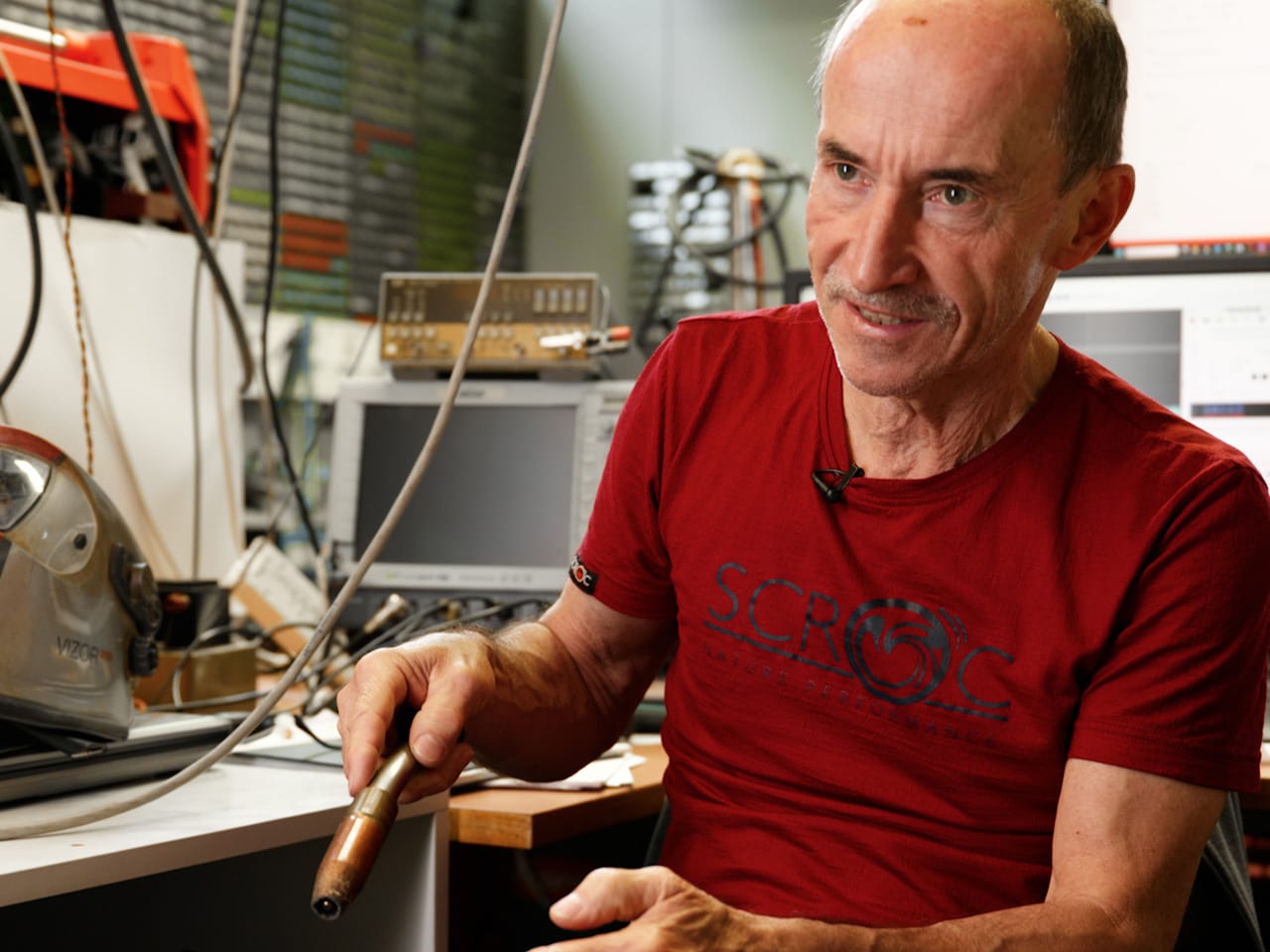

The technology’s roots trace back to a modest fix for corroding light-bulb sockets at Osram. Early prototypes proved the concept of spatter-free ignition, but wire-drive inertia capped performance at ten forward-back strokes per second. Fronius engineers, led by Josef “Joe” Artelsmair, persisted: a gearless drive and precise current-wire-speed synchronisation eventually pushed CMT into production-grade territory, giving fabricators stable arcs on ultra-thin metals and making laser-like seams possible with MIG equipment.

CMT’s advantage is precise control: the gear-less drive snaps the wire back up to 70 times a second while the current momentarily drops to a few amps, so each droplet detaches at roughly 0.3 kJ/mm of arc energy. The ultra-cool transfer keeps thin sheet flat, leaves almost no spatter, and even fuses galvanized steel to aluminium without burning off zinc. Add-ons like CMT Pulse and CMT Twin lift deposition beyond 8 kg/h for heavier work yet keep the same tidy bead profile. Twenty years on, it’s still the benchmark for proving that smart control beats brute heat.

Read the full story here.

Discussion