Fraunhofer IWS Pushes Filler-Free Laser Welding Forward

Laser welding is moving fast, and Fraunhofer IWS is showing just how far it can go. At the upcoming SCHWEISSEN & SCHNEIDEN 2025 in Essen, the institute will present dynamic beam shaping solutions that eliminate filler wire while improving efficiency and weld quality. The concept is simple but powerful: guide the beam intelligently, stabilize the melt pool, and achieve strong welds with less energy and less rework. This approach has already found footing in industries like e-mobility, aerospace, and heavy steel construction.

One example comes from the EU’s Albatross project, where researchers built aluminium battery housings for electric vehicles. Normally, combining die-cast aluminium with extrusion alloys means dealing with pores and hot cracks. By oscillating the laser beam, Fraunhofer reduced these defects, producing robust welds without extra filler material. The component has already been tested in a real vehicle, and further work is focusing on scaling the process for recycled aluminium and more complex cast joints.

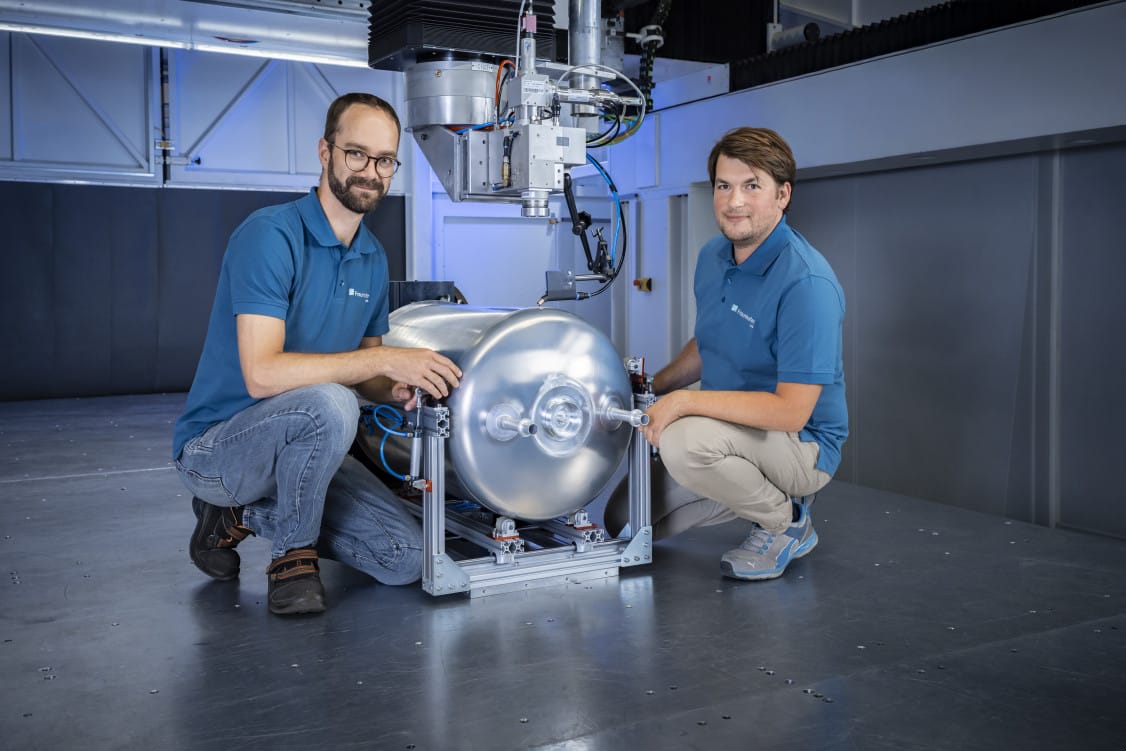

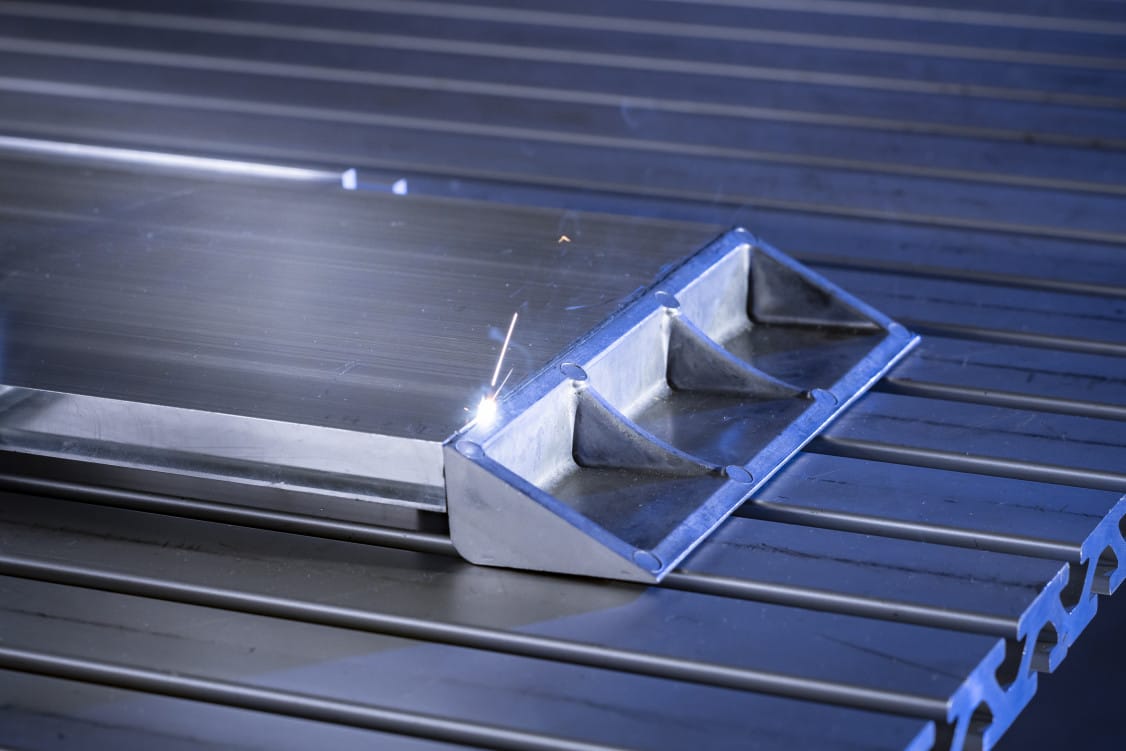

The same principle has been applied to aerospace tank structures, where high-strength aluminium alloys usually require filler to avoid cracking. The new laser process achieves crack-free welds without filler, even on curved 3D contours. In heavy steel construction, Fraunhofer’s 24 kW multilayer laser welding has proven its worth on crane booms, cutting filler use by up to 90% and reducing distortion to the point where straightening steps can often be skipped. Early industry response suggests strong interest, especially in bridge building, shipbuilding, and wind energy.

Source:

Discussion