Augmentus Received $11M to Advance Adaptive Welding Robots

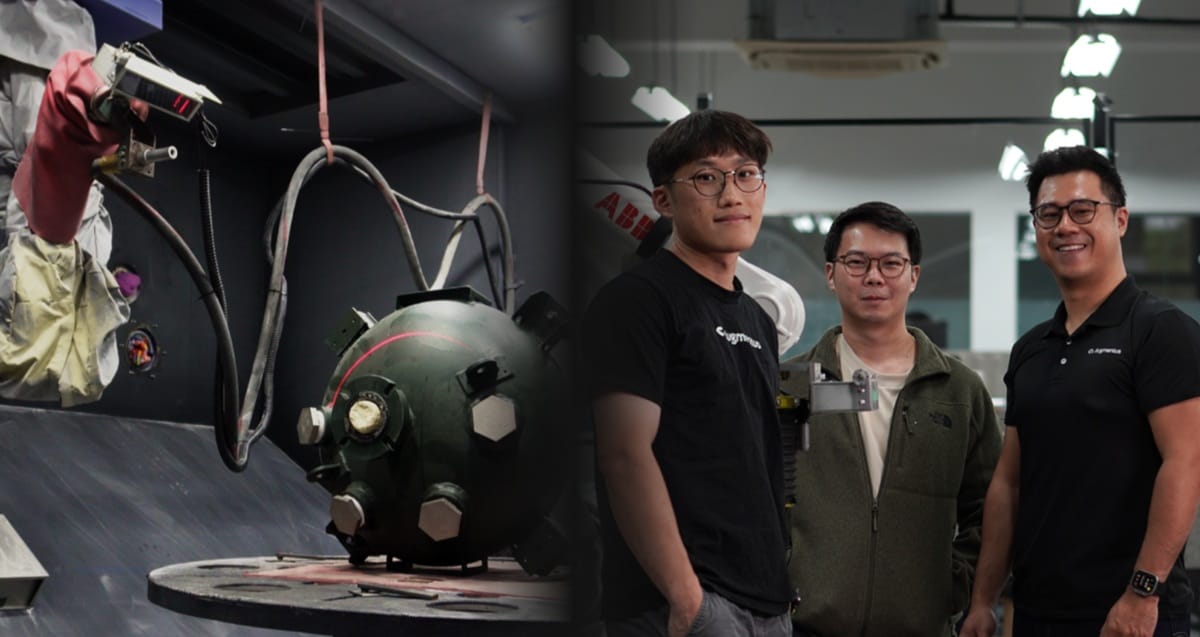

In the world of robotic welding, one of the toughest nuts to crack is automating tasks in unpredictable, high-mix environments. Augmentus, a Singapore-based robotics company, is now pushing that boundary further. Backed by a new $11 million Series A+ funding round, the company plans to scale its autonomous welding and surface finishing systems while expanding R&D into AI-powered robotics that can adapt on the fly. The investment was led by Woori VP and supported by EDBI, Sierra Ventures, and Cocoon Capital.

The main draw here isn’t just the tech—it’s the fact that this system eliminates the need for manual programming. For welders and manufacturers alike, that’s a serious relief. Programming a robot from scratch can take days. Augmentus brings that down to minutes with a combination of 3D scanning, adaptive motion control, and AI-driven path planning. No-code robotics isn’t just hype here—it’s a functional shift that could let small shops with limited automation expertise bring advanced robotics into their production without specialist teams.

With over 50 systems already in operation across six countries, Augmentus is moving beyond pilot phases and into full deployment. Their focus now includes working with system integrators and direct clients to meet growing demand—especially in complex tasks like welding, shot peening, and surface prep. Integrators like Sentenso GmbH have already noted improvements in setup speed and flexibility, a crucial win in time-sensitive manufacturing cycles.

The company says this funding round isn’t about chasing buzzwords—it’s about delivering tech that works in the gritty reality of shop floors. For welders who know how fast a job can change from one workpiece to the next, that adaptability isn’t just convenient—it’s essential. And for a younger generation looking to step into the trade through more tech-savvy paths, this kind of system could make welding automation more accessible than ever.

Source:

Discussion