AI and Welders Watch Over Nuclear Projects in Real Time

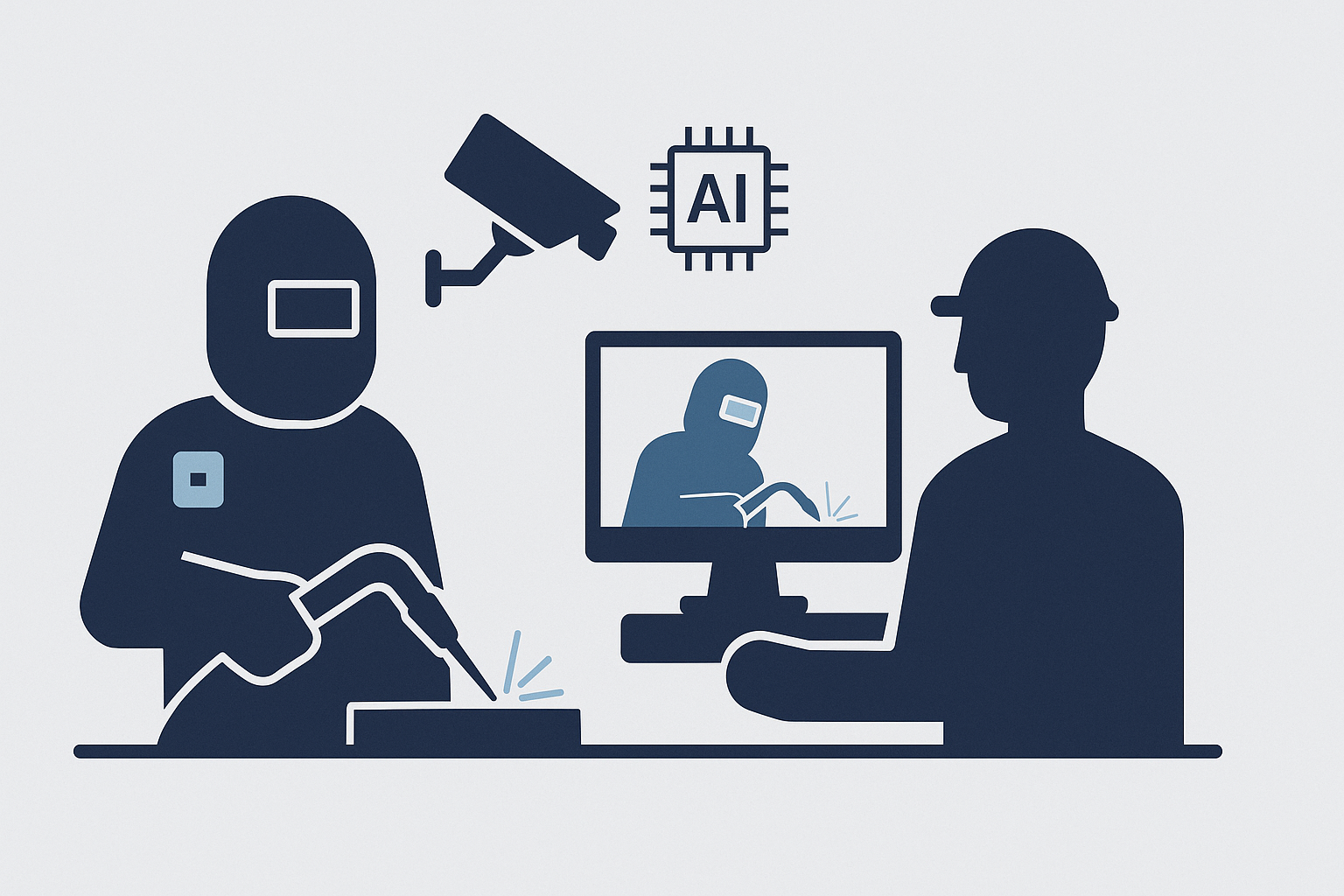

At the Haiyang nuclear power plant’s second-phase construction site in Shandong, welders are part of a tightly integrated safety and quality control process that reflects the scale and sensitivity of nuclear infrastructure work. Each welder is equipped with a personal recording device, and all footage is uploaded at the end of every shift. These recordings, along with live surveillance from nearly 1,000 strategically placed cameras, are reviewed both by AI and human safety officers. The dual system isn’t just about oversight—it’s about accountability and traceability, especially in a sector where even a minor welding defect could have major implications.

What stands out here is the clear recognition that welding in nuclear environments isn’t just a technical skill—it’s a certified responsibility. Different sections of the facility require different welding qualifications. The recording devices don’t just watch for mistakes; they help welders verify their work and protect themselves if questions of quality arise later. That kind of record-keeping isn’t just surveillance—it’s also a tool for professional integrity.

With more than 9,000 workers on-site and complex crane operations across a site the size of four soccer fields, the intelligent supervision system is also helping to prevent mechanical collisions and spot unsafe behaviors, like failing to wear safety harnesses. It’s a hybrid approach—machines handling volume and consistency, humans catching context and intent. It’s also a model that could hint at what’s coming in other high-risk welding sectors, where quality, safety, and documentation are tightly interlinked.

Source:

Discussion